Special promotions are available! Don't miss out on great deals!

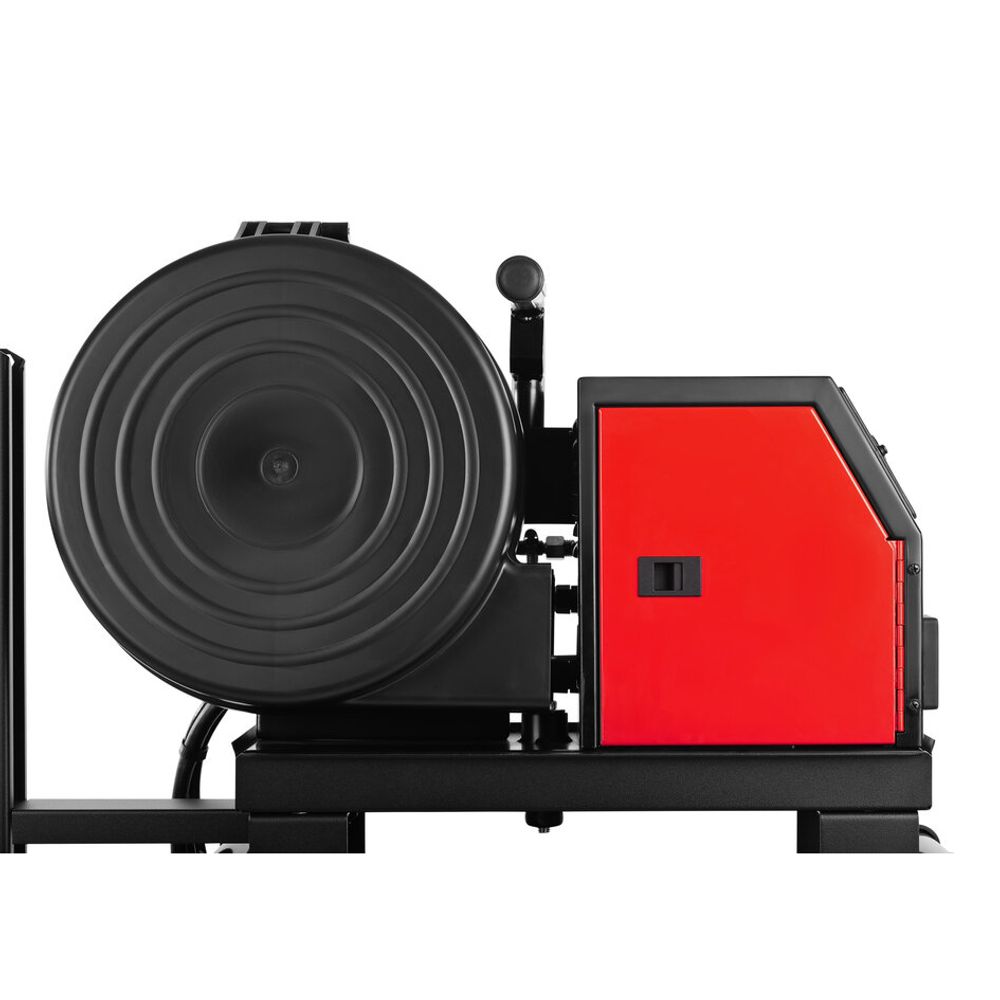

MIG-MAG/BRAZING/TIG/MMA/GOUGING Supermig 450i Pack+trolley welding machine 3ph, 230V/400V, Telwin

Product code: 816905

Brand: Telwin

Product description

- This welding machine is a 400A source of current for arc welding, made specifically for MAG welding carbon steel or weak alloys with CO2 protective gas or Argon/CO2 mixes, using full or core electrode wires (tubular). It is also ideal for MIG welding stainless steel with Argon gas containing + 1-2% oxygen and aluminium and CuSi3, CuAl8 (brazing) with Argon gas, using electrode wires that are suitable for the workpiece to be welded.

- It is particularly suitable for light metalwork fabrication and in body shops, for welding galvanized plates, high stress stainless steel and aluminium. SYNERGIC operation ensures fast and easy welding parameter setting, always guaranteeing high arc control and welding quality.

- The welding machine can be used for TIG welding in direct current (DC), with arc striking upon contact (LIFT ARC mode). It welds all types of steel (carbon, low- and high-alloy) and heavy metals (copper, nickel, titanium and their alloys) with a gas shield of pure (99.9%) Ar or, for special uses, with an Argon/Helium mix. It can also be used for MMA electrode welding in direct current (DC) using coated electrodes (rutile, acid, basic).

Key features

- MIG-MAG/FLUX mode with synergic (material thickness selection) or manual operation. Operating mode with wire feeder unit or in CV mode.

- FLUX (Cored Wire Welding): it is a process in which the heat required for welding is provided by an electric arc maintained between the piece to be welded and the electrode wire.

- MMA - PULSED MMA: Direct current and pulsed welding. Pulsed mode ensures Excellent results with basic electrodes and in position welding. less spray and reworking, higher quality welding seam.

- TIG DC-Lift welding. The precise strike in contact with the workpiece guarantees quality welding in steel, stainless steel, copper, etc.

BRAZING: it is an assembly operation that is obtained by melting a filler metal (for example silver or tin-based alloys) without melting the base metal. Brazing therefore allows the edges of the joint to be kept intact. - Flexibility of use with different materials (steel, stainless steel, high-strength steel, aluminium, etc.) and wide variety of fields of application (industry, metalwork, construction, etc.).

- The fast SYNERGIC adjustment of the welding parameters thanks to the "ONE TOUCH" technology, makes the product very easy to use. Just set the material thickness and start welding.

- Can be used with 300mm reels, max. 15 kg

- Electronic reactance: Adjusting the reactance during MIG/MAG welding allows you to fine-tune the inductance of the welding circuit. By adjusting the reactance, the welder can optimize the behavior of the welding arc when welding different material thicknesses and types, improving the quality of welding and facilitating the welding process.

- Wire upslope: This setting allows you to gradually increase the speed of the welding wire at the beginning of welding. This helps reduce welding errors such as excessive penetration or spatter when the arc is struck, ensuring a smoother start and transition in the welding process.

- Wire burnback time setting: This setting controls the amount of time the wire can "burn back" after welding is complete before it automatically stops. Setting the proper burnback time ensures that the wire does not burn back too short, making it easier to start the next welding cycle.

- Post-gas setting: This function controls the amount of time that shielding gas continues to flow after welding is completed to protect the still-hot weld from airborne contaminants until it cools down.

- The ATC (Advanced Thermal Control) technology, made by Telwin, allows excellent welds on thin surfaces to be obtained with great ease thanks to advanced arc control. The particular instantaneous control of the welding arc and the ultra rapid correcting of parameters minimize current spikes, something that is characteristic of Short Arc transfer procedures, to the advantage of a low thermal load on the piece to be welded. The result, on the one hand, is reduced deformation of materials and, on the other, a fluid and accurate transfer of the weld material and the creation of a welding seam that is easy to model.

Advantages:

- easy welding of thin materials;

- decreased deformation of material;

- stable arc even when working with low currents;

- rapid and accurate spot welding;

- easier coupling of spaced sheets. - GOUGING with carbon electrodes to eliminate excess material, for revised welding, for material cutting or workpiece preparation.

- Particular construction of the ventilation system which, following a dedicated tunnel, allows preservation of the electronic components from dirt and dust.

- The graphic display allows a clear view of the main welding parameters and product settings.

- Electrode welding is possible in both direct and pulse current modes. The pulse mode (MMA Pulse) is recommended for basic electrodes and positional welding and guarantees less spatter and rework and higher weld quality.

- Protection devices: thermostat, overvoltage (+15%), undervoltage (-25%), overcurrent, motor-generator.

- Designed to last. The compact and solid structure was designed for use in various work environments: from production to metal structural works, from building sites to mechanical workshops.

- Light weight and compactness also ensure easy portability to all locations, both indoors and outdoors.

- High energy saving.

- Backlit LCD display.

MIG-MAG

- Operating modes:

- Manual;

- Synergic;

- 40 Predefined synergy curves, post gas: Use to adapt the protective gas outflow starting from when welding is stopped. Settings from 0 to 10 seconds. Factory value: 1 sec.

- Settings on the wire feed unit: manual wire feed, weld seam setting, wire feed speed (MAN mode) and welding power (SYN mode)

- LCD display of wire speed, welding voltage and current

- Possibility of connecting a semi-automatic wire feed unit (CV)

- Selection of 2T/4T time operation and spot

- 2T: welding begins when the torch push-button is pressed and ends when the push-button is released.

- 4T: welding begins when the torch push-button is pressed and released, and ends only when the torch push-button is pressed and released a second time. This mode is useful for long welding operations.

- Spot welding mode: used for MIG/MAG spot welding with control of welding duration.

TIG

- Start LIFT: The electric arc is struck by moving the tungsten electrode away from the piece to be welded. This strike mode causes less electrical-radiation disturbance and reduces tungsten inclusions and electrode wear to a minimum.

- Welding voltage and current shown on an LCD screen.

MMA

- Operating modes:

- Direct current MMA;

- Pulse current MMA;

- Arc force (DYNAMIC ARC) and welding current adjustment. This helps maintain a stable arc even in difficult conditions, such as dense welds. With the Arc Force function, the inverter automatically adjusts the current depending on the length of the arc. If the arc accidentally touches the workpiece, the current increases, so it does not stick. If the two are too far apart, the current will be reduced and the arc will not extinguish.

- Hot Start function helps to ignite the arc more easily by automatically increasing the current at the beginning of the welding process. This can be especially useful for difficult-to-ignite electrodes. Facilitates arc ignition for materials that are too cold or too thick.

- VRD device for greater safety. Enabling/disabling the “Voltage Reduction Device” for a safe start at low voltage. The VRD function allows to decrease the output voltage, increasing the operator’s safety when working in humid or particularly dusty environments.

- The Anti-Stick function prevents the electrode from sticking to the workpiece, reducing the current connected to the electrode when it detects sticking. This makes it easier to remove the electrode and reduces the risk of overheating.

- Welding voltage and current shown on an LCD screen.

GOUGING

- Gouging voltage and current shown on an LCD screen.

OTHER

- Setting the metric or UK system.

- Possibility of connecting a semi-automatic type wire feeder unit (CV).

PROTECTION

- Thermostatic protection: A heat-sensing system that shuts down the machine if the temperature rises too high, preventing overheating.

- Protection against accidental short-circuits caused by contact between torch and earth.

- Protection against irregular voltage (power supply voltage too high or too low).

STANDARD ACCESSORIES

- MIG torch (MT36, 3m)

- Return cable complete with earth clamp

- Torch holder

- Trolley

Specifications

- Three phase mains voltage: 230/400V

- Mains frequency: 50/60Hz

- Current range: 20-320A/20-400A

- Max. current: 300A@40%/400A@40%

- DC current: 240/300A

- Max. no load voltage: 82/77V

- Max. absorbed current: 38/31A

- Absorbed current at 60%: 27/21A

- Max. absorbed power: 11/16kW

- Absorbed power at 60%: 7,9/10,8kW

- Efficiency: 89%

- Power factor: 0,74

- Usable electrodes in DC: 1,6-8mm

- Steel welding wire diameter: 0,6-1,6mm

- Inox welding wire diameter: 0,8-1,6mm

- Aluminium welding wire diameter: 0,8-1,6mm

- Flux cored welding wire diameter: 1-1,2mm

- Brazing wire diameter: 0,8-1,2mm

- Protection degree: IP23

- Dimensions: 100x50x110cm

- Weight: 69kg

Product packing

| Pack number | Dimensions | Weight |

|---|---|---|

| 1 | 115 x 105 x 55 cm | 75.6 kg |

Delivery fee

| Delivery method | Gross price |

|---|---|

| Pickup in Nagytarcsa | 0,00 € |

| Pickup in Debrecen | 0,00 € |