Special promotions are available! Don't miss out on great deals!

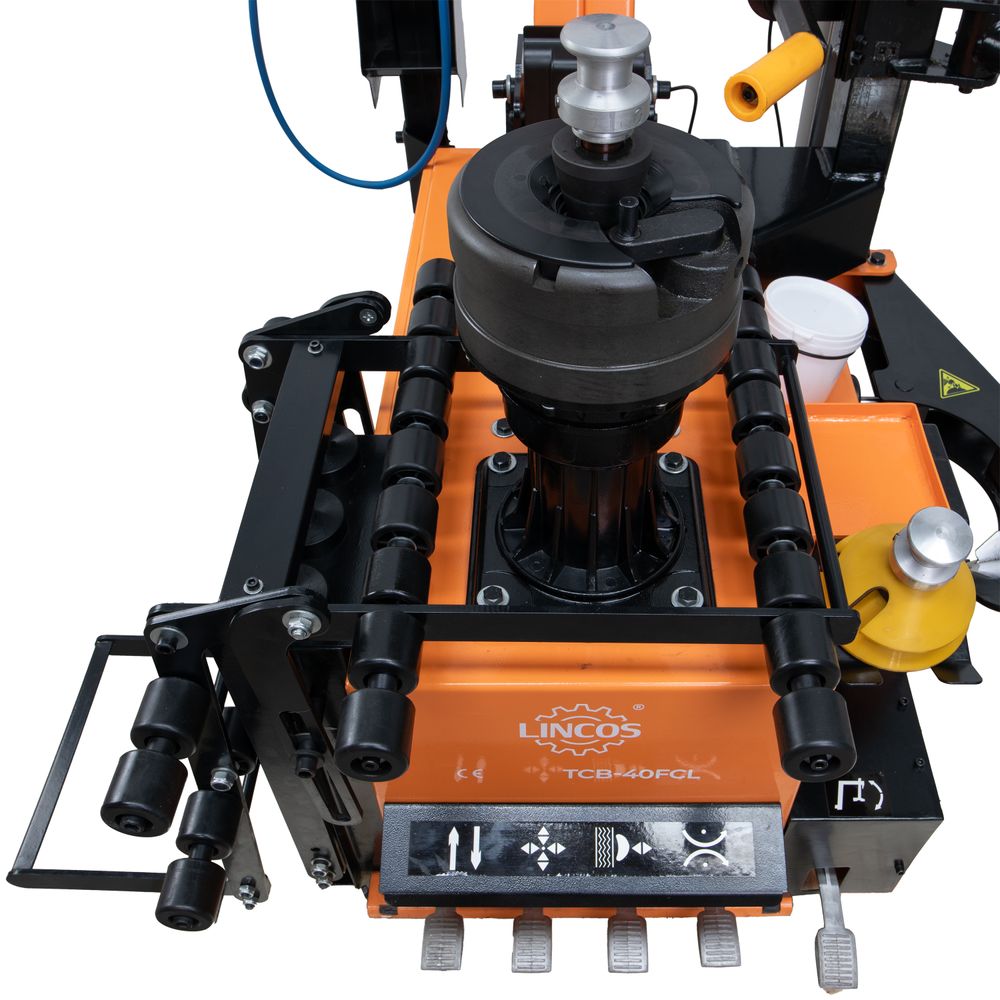

Leverless tyre changer, 26", tiltable and lockable column, help arm, variable speed, wheel lift, 230V

Product code: TCB-40FCL

Brand: Lincos

Product description

Description

Variable turntable speed controlled by foot pedal. The built-in wheel lift ensures precise placement and handling of wheels. The machine, featuring a large 26" clamping table and auxiliary arms, is especially recommended for mounting run-flat tires. Premium-grade tire changer highly recommended for workshops frequently handling low-profile tires.

Tire changer with tilting mounting column, pneumatically adjustable auxiliary arms, and an analog stand-mounted tire inflation gun. Leverless operation, with a uniquely designed mounting head gently slipping between the rim and tire without damage during demounting and mounting.

The equipment includes numerous accessories that facilitate work and spare buyers from extra expenses. Accessories include edge protectors, rim protectors, mounting head protectors, a brush, tire mounting paste, etc.

Recommended for tire workshops and automotive repair shops. Its special design (tilting column), auxiliary arms (horizontal rollers, bead pressing tool, etc.), and unique mounting head make this machine ideal for handling special and run-flat tires.

Tire Changer Machine Operation

- Unscrew and remove the valve from the tire, letting out all air completely.

- Use the pneumatic bead breaker on the side of the machine to separate the tire from the rim. Rotate the wheel repeatedly until the tire fully disengages from the rim.

- The plastic bead breaker edge-guard accessory prevents damage when working with delicate alloy wheels.

- Accessories include a brush and tire mounting paste; use these to thoroughly lubricate both sides of the tire.

- Position the wheel onto the integrated wheel lift and raise it horizontally by pressing the foot pedal. Move the lifted wheel above the clamping table, and carefully place it onto the table, ensuring the small locking pin engages into one of the wheel bolt holes.

- Select the appropriate center shaft length and cone. Insert them in the center of the clamping table and lock them in place using the foot pedal. For alloy wheels, it's advised to use the provided plastic-coated cone to avoid rim damage.

- The pillar supporting the mounting head can be tilted back pneumatically, simplifying tire positioning.

- After aligning the mounting head with the rim, secure it pneumatically by pressing the yellow button located on the mounting column.

- The mounting head's plastic protectors help prevent scratches or marks on the rim.

- After securing the mounting head, pneumatically insert it between the rim and tire to facilitate tire demounting.

- Rotate the turntable to separate the tire from the rim. Turntable rotation speed can be smoothly adjusted by pressing the foot pedal.

- Repeat steps starting from step 7 on the inner side of the rim.

The auxiliary arm's bead press and horizontal rollers greatly aid the remounting of run-flat, reinforced sidewall, or low-profile tires.

Accessories

- 2 pcs center locking shafts

- 3 pcs cones, including 2 pcs plastic protection covers

- Mounting lever

- Tire lubricant paste

- Brush

- Set of plastic mounting head protectors (3 sets), pre-installed

- Plastic bead breaker edge guard, pre-installed

- Rim protector

- Plastic scraper

- Air-water separator and lubricator

- Spare snap ring set

Product packing

| Pack number | Dimensions | Weight |

|---|---|---|

| 1 | 120 x 95 x 102 cm | 390 kg |

| 2 | 122 x 45 x 45 cm | 55 kg |

Delivery fee

| Delivery method | Gross price |

|---|---|

| Pickup in Nagytarcsa | 0,00 € |

| Pickup in Debrecen | 0,00 € |