Special promotions are available! Don't miss out on great deals!

Stand for washing of particulate filters (DPF, FAP)

Product code: MS900

Brand: MSG

Product description

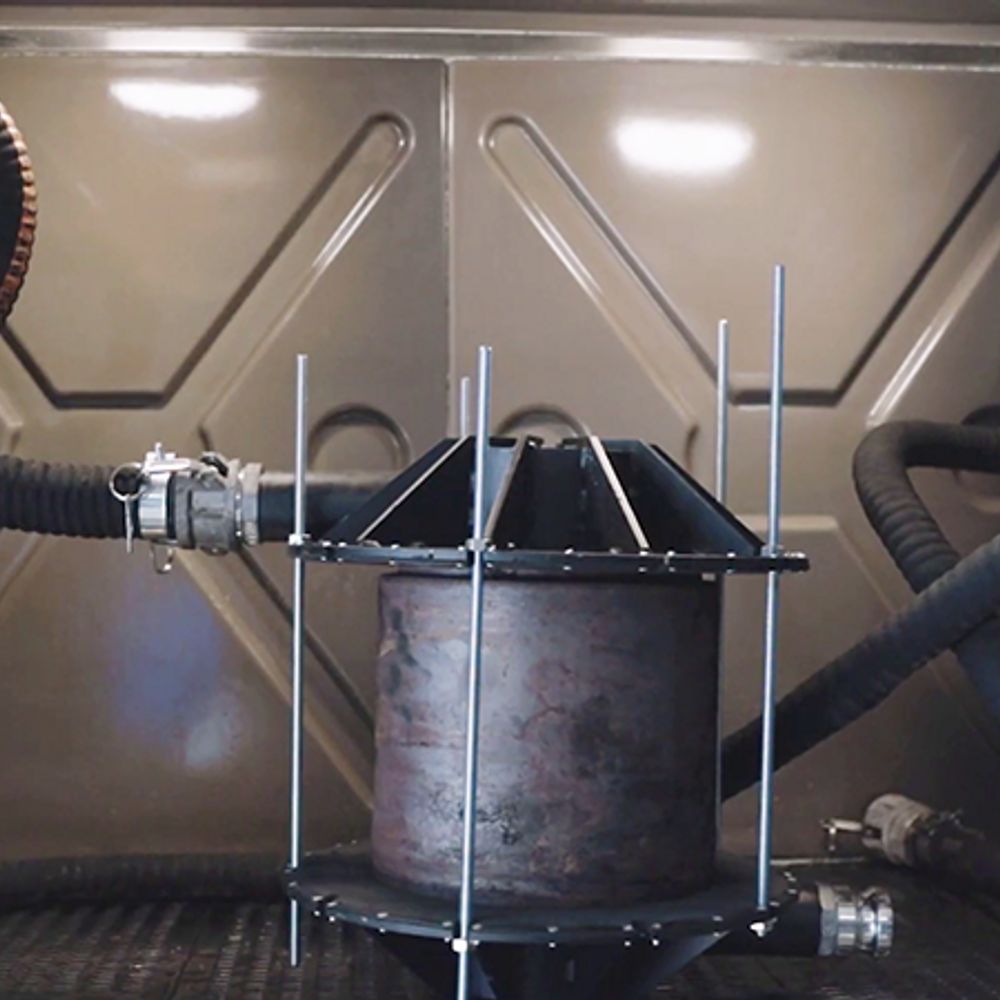

Diesel particulate filters (DPF) eventually become clogged with soot and ash, which reduces engine performance and increases emissions. The MS900 washing rack offers an innovative solution for thoroughly cleaning filters without the use of chemical cleaning agents. The system uses a warm water flow that periodically reverses direction, effectively removing contaminants from the filter surfaces. This process is supported by compressed air pulses that further enhance cleaning efficiency.

Designed specifically for rinsing and cleaning particulate filters, the MS900 employs the most effective rinsing method by reversing the liquid flow direction. Changing the flow direction enhances the detachment of soot and ash from the filter surfaces, a process reinforced by pulses of compressed air. This results in excellent cleaning quality without the need for special chemicals.

The cleaning process of the MS900 rack consists of four steps

- Filter inspection – 1 minute

- Rinsing – 30-60 minutes

- Drying – 15-20 minutes

- Re-inspection – 1 minute

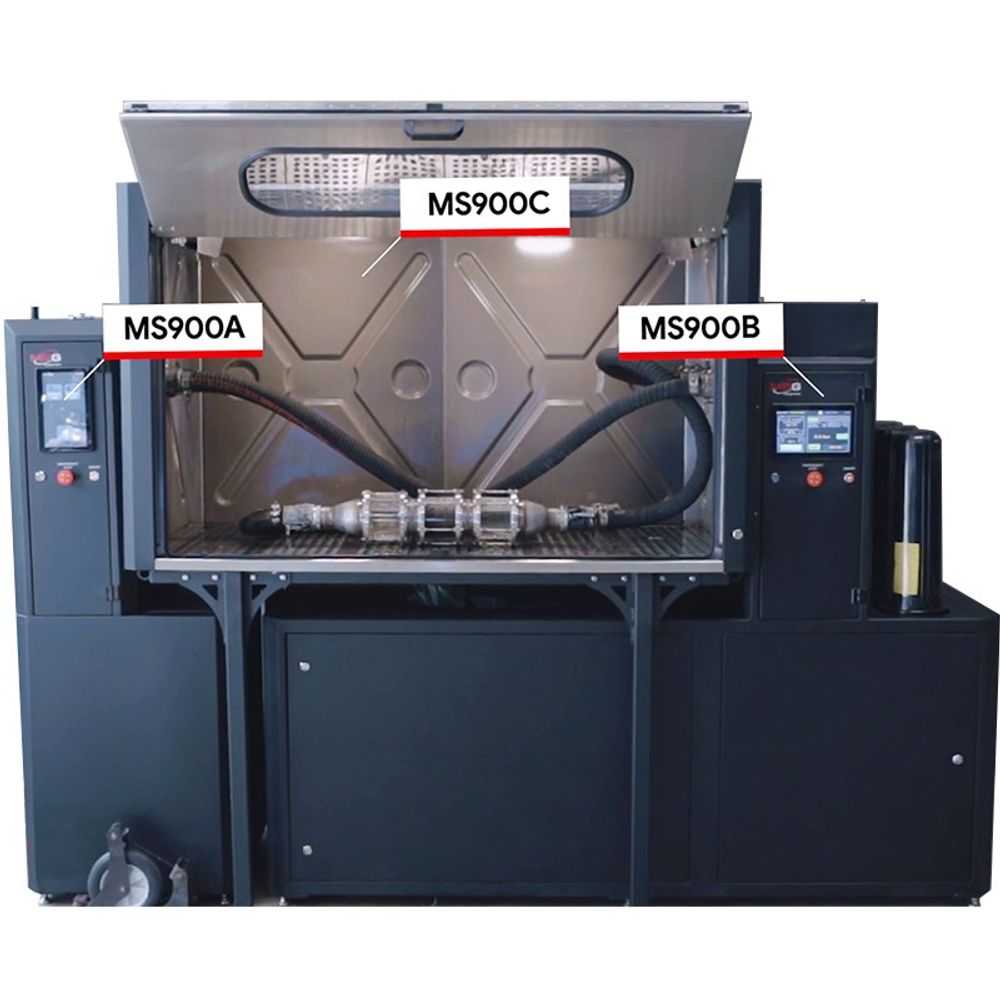

The system is composed of three modules

- MS900A – Diagnostic and drying module

- MS900B – Cleaning module

- MS900C – Washing and drying chamber

This design enables simultaneous washing and drying of filters, thereby increasing productivity and reducing maintenance time. The user-friendly touchscreen interface simplifies operation and allows for pre-setting of cleaning parameters for the most common filter types.

Thanks to its modular design, the MS900 can wash and dry particulate filters simultaneously, effectively doubling productivity compared to conventional systems with sequential operations.

To facilitate tracking of maintained filters, the rack stores the rinsing results and can print them via an external Bluetooth printer (included in the kit).

The rack is equipped with numerous connection interfaces, allowing for integration of particulate filters from various passenger vehicles and trucks.

Key Features

- Chemical-free cleaning: Uses only warm water and compressed air, providing an environmentally friendly solution.

- Short cleaning time: The process takes between 30-60 minutes, depending on the type.

- High productivity: The modular design permits simultaneous cleaning and drying of multiple filters.

- Data backup and printing: The system stores cleaning results and provides the option to print them via a Bluetooth printer.

- Safe operation: The enclosed cleaning process ensures a clean work area and minimizes contact with hazardous substances.

Advantages

- Cost-effective particulate filter rinsing

- Versatility

- Short cleaning time

- High productivity

- User-friendly design

- Storage and printing of results

- Safe operation

- Easy transportation and installation

- Free software updates

Technical Specifications

Below are the technical specifications of the MS900 particulate filter washing rack:

| Property | Value |

|---|---|

| Supply Voltage | 400 V and 230 V |

| Type of Electrical Connection | Three-phase and single-phase |

| MS900A Module Power Consumption | Maximum: 12 kW Rated: 9.3 kW |

| MS900B Module Power Consumption | Maximum: 10.5 kW Rated: 8.25 kW |

| MS900C Module Power Consumption | 0.02 kW |

| Dimensions (H×W×D) | 2750×860×2070 mm |

| Total Weight | 400 kg |

| Control | Touchscreen |

| Cleanable Filter Types | DPF (DPF + SCR), FAP (FAP + SCR), GPF |

| Drying Air Temperature | Up to 80°C |

| Washing Chamber Dimensions (W×D×H) | 1600×750×955 mm |

| Work Area Lighting | Available |

| Exhaust Ventilation System | Yes (recommended), minimum 300 m³/h |

| Type of Washing Fluid | Water |

| Washing Fluid Temperature | Up to 60°C |

| Washing Fluid Filter System | Tank filter, hydrocyclone, 3 x BB20 filters (5-20 microns) |

| Water Tank Capacity | 250 liters |

| Compressed Air Connection | 6-8 bar, 200 l/min |

| Storage and Printing of Cleaning Results | Available, via an external Bluetooth printer |

| Software Updates | Available (free) |

Product packing

| Pack number | Dimensions | Weight |

|---|---|---|

| 1 | 78 x 91 x 185 cm | 199 kg |

| 2 | 220 x 85 x 190 cm | 306 kg |

| 3 | 180 x 100 x 220 cm | 321 kg |

Delivery fee

| Delivery method | Gross price |

|---|---|

| Pickup in Nagytarcsa | 0,00 € |

| Pickup in Debrecen | 0,00 € |